Pipe clamp is important additives applied in a massive shape of industries. These clamps are a characteristic device to secure pipes or tubes, making sure they stay in area and feature effectively. They are available in awesome sizes, materials, and designs to fulfill the dreams of several programs. In this article, we’re able to discover what clamps are, their types, uses, and installation techniques.

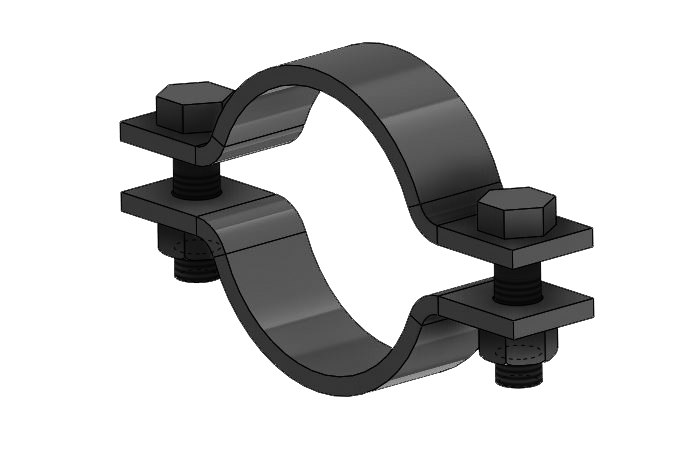

What is a Pipe Clamp?

A pipe clamp is a device used to lock, maintain, or at ease a pipe in vicinity. It typically includes a band or collar that encircles the pipe and a screw or bolt that tightens the clamp. clamps make certain pipes stay stable and aligned, preventing movement or harm over time. They furthermore assist in dealing with pipe vibrations and soaking up stresses.

Purpose and Function of Pipe Clamps

The primary characteristic of a pipe clamp is to preserve pipes securely in the region. By doing so, clamps prevent unwanted movements that might cause harm or leaks. These clamps are frequently completed in plumbing, heating, air float, and enterprise systems. They provide balance to the pipes, thinking of clean fluid or gasoline going along with the go with the flow via them.

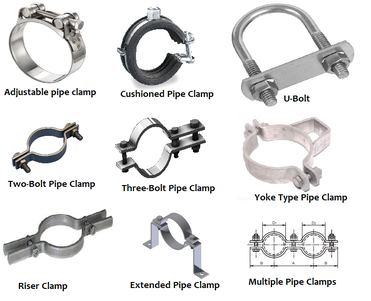

Types of Pipe Clamps

There are several unique styles of pipe clamps, each designed for precise programs. These clamps are to be had several sizes, shapes, and substances. The most not unusual sorts of clamps embody:

1. U-Bolt

U-bolt clamps are one of the most famous sorts. They encompass a U-well known bolt that suits the course of the pipe. Two nuts comfy the U-bolt in region, fastening the pipe to a ground or bracket. U-bolt clamps are awesome for heavy-obligation applications and are often used in plumbing, car, and commercial enterprise commercial enterprise enterprise agency systems.

2. Strap Clamps

Strap clamps characteristic a flat, bendy strap that wraps within the path of the pipe. These clamps are secured thru manner of bolts or screws, tightening the strap at some point of the pipe. Strap clamps are normally carried out in situations in which a custom in shape is wanted. They are regularly used for smaller pipes or in regions in which a famous clamp can also not be healthy.

3. Spring Pipe Clamps

Spring clamps use anxiety springs to relax pipes in the area. These clamps are best for applications wherein vibration or motion is a venture. The spring mechanism allows it to take in shocks and prevent damage. Spring clamps are generally implemented in HVAC systems and devices wherein pipe movement isn’t uncommon.

4. Adjustable Clamps

As the choice suggests, adjustable pipe clamps may be modified to wholesome several pipe sizes. These clamps feature an adjustable band that may be improved or shrunk to cope with wonderful diameters. They are flexible and appropriate for plenty of industries, together with creation and production.

You may like barbie halloween costume

Materials Used in Pipe Clamps

clamps are made from a variety of materials, relying on their supposed use. The fabric choice affects the durability, energy, and corrosion resistance of the clamp. The most common materials implemented in clamp introduction encompass:

1. Steel

Steel is one of the most not unusual substances used for clamps. It is robust, durable, and capable of withstanding immoderate stress and heavy hundreds. Steel clamps are exceptional for heavy-obligation programs and offer prolonged-lasting elegant crucial performance.

2. Stainless Steel

Stainless steel clamps are better to rust and corrosion. These clamps are best to be used in outdoor environments or regions with publicity to moisture. Stainless metal is used in plumbing, HVAC structures.

3. Plastic

They are normally achieved in packages in which weight is a topic. Plastic clamps are suitable for smaller pipes and systems in which immoderate energy isn’t always required.

4. Zinc-Plated Steel

Zinc-plated metal clamps provide the electricity of metal combined with extra corrosion safety. The zinc coating prevents rust and oxidation, making them remarkable for out of doors or excessive-moisture packages. Zinc-plated metallic clamps are frequently completed in plumbing and automobile systems.

Applications of Pipe Clamps

Pipe clamps are accomplished in a huge shape of industries due to their versatility. They are crucial in structures in which pipe alignment, assist, and balance are crucial. Some of the most not unusual packages encompass:

1. Plumbing

They help preserve the pipe’s characteristics and prevent movement, ensuring inexperienced water flow. clamps are mainly important in big plumbing structures, inclusive of these decided in commercial enterprise homes or business centers.

2. HVAC Systems

In HVAC (heating, air go together with the glide, and aircon) systems, clamps are used to at ease ducts, pipes, and tubes that supply air or refrigerants. These clamps assist maintain the stability of the device and reduce vibrations, ensuring clean and green operation.

3. Automotive

In vehicle systems, pipe clamps comfy exhaust pipes, gas traces, and brake traces. These clamps prevent vibrations, securing the pipes and making sure proper functioning of the car’s structures. Automotive clamps are frequently crafted from chrome steel or unique durable substances for maximum strength.

4. Electrical and Cable Management

Pipe clamps are occasionally implemented in electric powered systems to comfy cables or wires. They save you cables from shifting or turning into tangled, making sure safety and ordinary performance. In the ones packages, plastic or rubberized clamps are often used to prevent damage to the cables.

How to Install a Clamp

Installing a pipe clamp is a clean way, but proper set up is vital for making sure that the pipe is securely held in place. Below is a step-thru manner of-step guide for putting in a large clamp:

Step 1: Measure the Pipe

Before deciding on a clamp, degree the diameter of the pipe to make sure you choose out the excellent period. If the clamp is surely too small or too massive, it’ll now not provide precise sufficient assist.

Step 2: Position the Clamp

Place the clamp at a few levels within the pipe at the famous region. Ensure the clamp is located in a manner that lets in the pipe to be properly secured.

Step 3: Tighten the Clamp

Using a wrench, screws at the clamp. Ensure the clamp is fixed, however be careful now not to overtighten, as this can harm the pipe or the clamp.

Step 4: Test the Installation

Once the clamp is secured, check the pipe to ensure it is strong and nicely aligned. Make tremendous sense that the pipe isn’t always shifting or transferring and that the clamp is presenting enough guidance.

Benefits of Using Clamps

Pipe clamps provide numerous key advantages, making them essential in lots of programs. Some of the primary blessings embody:

1. Stability

Pipe clamps offer balance through the manner of securing pipes in place. This prevents unwanted movement that would bring about leaks, pipe harm, or decreased common performance.

2. Vibration Reduction

In structures wherein pipes revel in vibrations, along facet HVAC or automobile structures, clamps help reduce those vibrations. This ensures smoother operation and extends the lifestyles of the pipes.

3. Versatility

Pipe clamps are available in a spread of sizes and designs, making them suitable for masses taken into consideration one in all. Whether you want to relax a small pipe or a massive industrial device, there may be a clamp designed for the undertaking.

Conclusion

Pipe clamps are vital components that provide stability, manual, and safety to pipes in numerous applications. Whether you’re strolling in plumbing, HVAC structures, vehicle, or manufacturing, choosing the right clamp is essential for ensuring the inexperienced operation of your device. With a huge sort of substances, sorts, and sizes available, clamps offer flexible solutions for any piping goals. Proper set up and safety of clamps are critical to maximize their effectiveness and prevent high priced safety inside the future.

Also read Bunkeralbum